EHRLE FS (Factory Subsidiary)

EHRLE FS SIA is a 100% subsidiary of EHRLE GmbH, located in Marupe, near Riga (Latvia).

Our corporate mission is to become the leading supplier of cleaning solutions in Europe.

EHRLE GmbH was established by EHRLE FS SIA to provide the highest level of customer support to customers in the Baltic region. Since 1961, EHRLE has been one of the leading manufacturers of high-pressure cleaners and car wash systems in Europe.

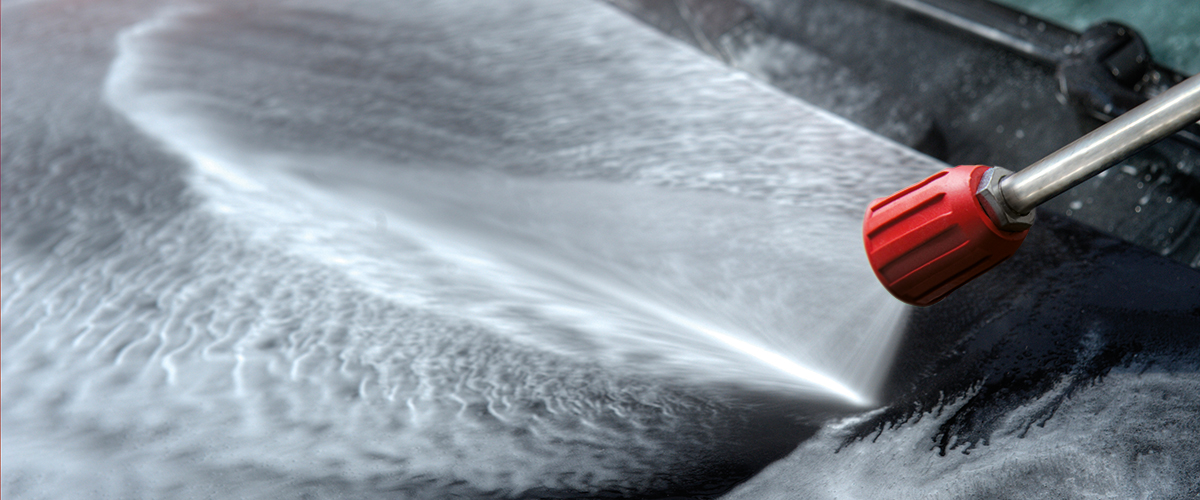

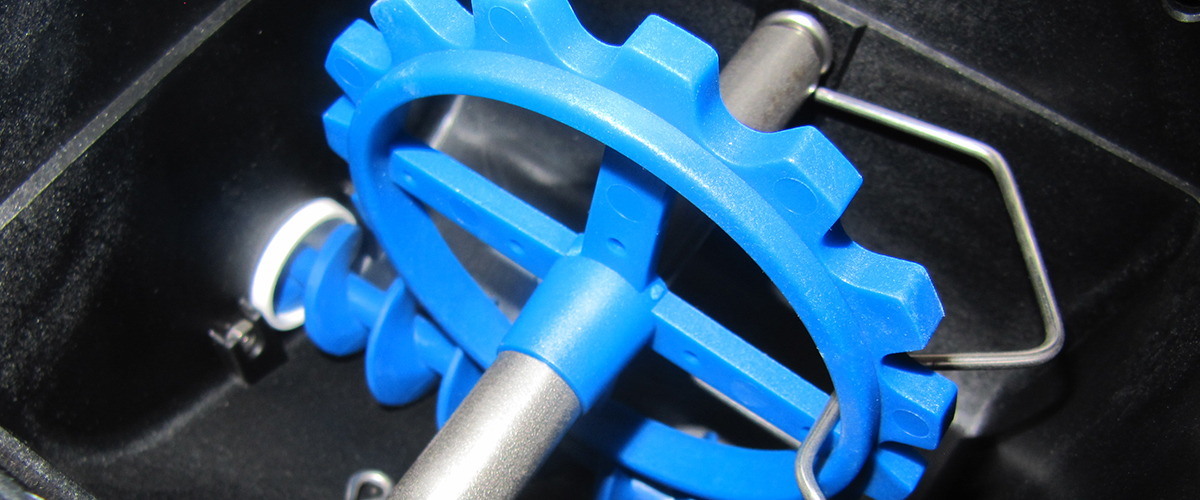

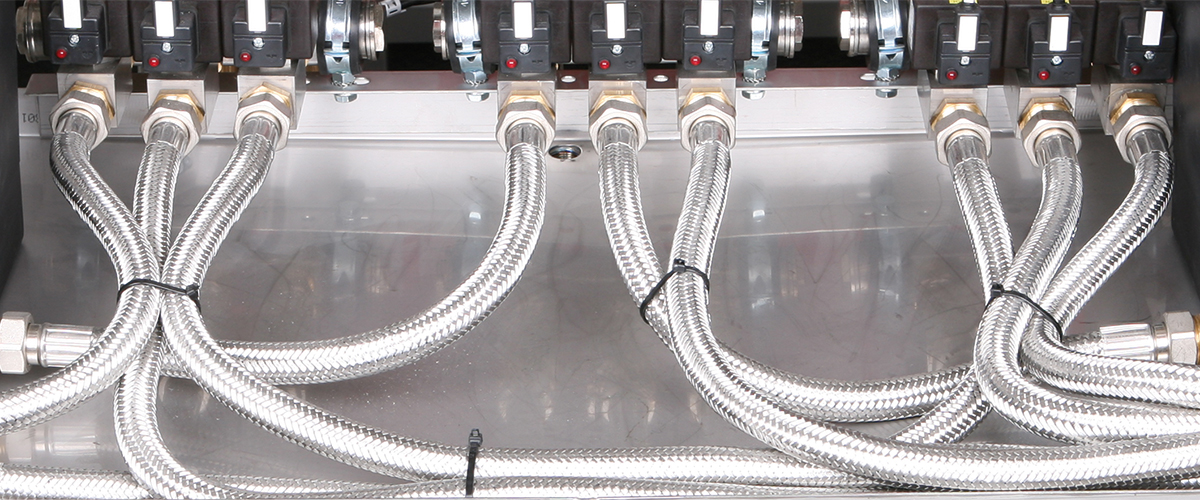

The product range is detailed in detail from portable and mobile high-pressure cleaners, stationary systems, each in cold and hot water versions, to industrial vacuum cleaners and application-specific accessories, as well as self-service car wash systems and car wash and care products:

- More than 117 different high-pressure cleaners and accessories for professional cleaning solutions

- To date, more than 5,000 self-service car washes have been installed across Europe

- A full range of car wash chemicals and care products

- Comprehensive service offer